The new tunnel greatly enhances the security, capacity and reliability of MWRA's entire water transmission system.

Until now, MWRA has relied on a single 1940's-era surface aqueduct, the Hultman Aqueduct, to serve all of Metro Boston. With its leaks and aging valves, the Hultman needed to be taken off-line for major repairs.

Before the MetroWest Tunnel, failure of the Hultman could have caused nearly complete interruption of Boston's water supply. This would have been a disaster for the region's public health, safety and economy.

MetroWest Water Supply Tunnel Quick Facts |

| Purpose: |

To enhance the security, capacity and reliability of the water system that serves 2.3 million people in 40 communities |

| Total Program Budget Set in 1995: |

$728 million |

| Total Program Estimated Completion Costs: |

$665 million (includes design, construction management, construction

and other support costs) |

| Awarded construction: |

8 contracts valued at over $506 million in construction costs |

| Length of tunnel: |

17.6 miles – roughly the distance from Rte. 495 to Rte 128, parallel to the Mass.Turnpike |

Installing forms for concrete lining 2001-2002

|

Diameter: |

Mined at 16 feet, finished at 14 feet |

Depth: |

200-500 feet deep |

Years to Complete each phase of construction: |

Excavating Shafts: 1 year

Mining: 2 years

Lining: 2 years

Line Shafts: 1 year

Piping, connections and disinfection: 1 year |

| Construction schedule and duration: |

Construction work took place over a 7-year period with over 6 million man-hours worked. Work proceeded 24 hours per day on 3 shifts, 5-6 days per week with no fatalities. |

| Mining: |

3 machines, each valued at over $7 million, were used to mine the tunnel

3 major working shafts: (Southborough,

Framingham and Weston)

9 connections to water facilities and communities |

| Under five communities: |

Marlborough, Southborough, Framingham,

Wayland, and Weston

Wye intersection 235 feet below the Mass. Turnpike tolls at Rte. 128 |

| Average production rate: |

57.1 feet per day

|

| Total rock excavated: |

1, 025,000 cubic yards |

| Kinds of Rock Excavated: |

Granite, gneiss, shist, quartzite and others |

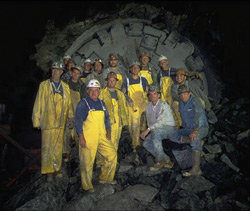

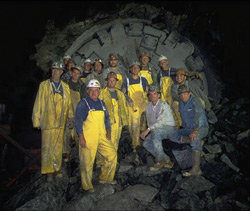

Workers inside the tunnel

|

| Total Amount of Concrete Used for Lining: |

184,722 cubic yards |

| Concrete Production Rate: |

154 cubic yards per day |

| Average production for lining: |

77 lineal feet per day |

| Project coordinated with: |

Treatment Facilities at Walnut

Hill (Marlborough) and Covered

Storage at Norumbega |

Reservoir (Weston)

capacity: |

450 million gallons per day |

| Amount of water needed to fill the tunnels and shafts: |

105.5 million gallons |

| Disinfected with: |

42,000 gallons of sodium

hypochlorite (chlorine) |

| Total Number of People Who Worked on the Project: |

1,907 |

Tunnel workers, a.k.a. "Sandhogs" pose in front

of their Tunnel Boring Machine after holethrough

|

| Maximum Number of People Working at One Time: |

598 |

| Unions on the Job: |

Tunnel Workers Local 88, Operators Local 4, Electricians Locals 103 and 96 |

| Schedule: |

Broke Ground late 1996

Finished construction on schedule in Spring 2003

Final Testing and Disinfection in Summer/early Fall 2003 |

| Memorandums of Agreement with Communities: |

Weston

Wayland

Framingham

Southborough |

| Designers: |

Sverdrup/Jacobs Civil Inc. |

| Construction Management Team: |

Stone and Webster Massachusetts Inc., a Shaw Group Co.

Parsons Brinckerhoff Construction Services Inc.

Regina Villa Associates

Hager GeoScience

H2O Engineering Consulting Assoc.

DMC Engineering

Judith Nitsch Engineering

Revet Environmental |

| Major Contractors: |

Shea/Traylor/Healy

Modern Continental/Obayashi

Barletta Heavy Division |